Product Category

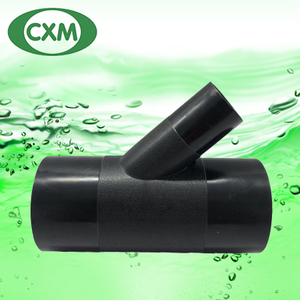

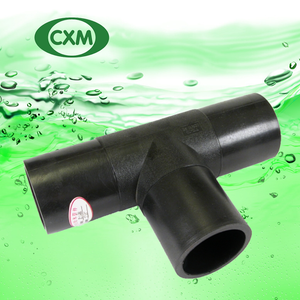

- Hdpe Pipes & fittings

- PPR pipes & fittings

- Plastic butt welding machine

- PP compression fittings

- Pipe cutters

- Pressure testing pump

- PP thread fittings

- CPVC pressure pipes & fittings

- CPVC & PVC-U valves & faucets

- PUV-U pipes & fittings

- NBR 5648 water supply fittings

- ASTM SCH40 insulating electrical pipes & fittings

- ASTM SCH80 water supply pipes & fittings

- BS thread pipes & fittings

- GB PN16 pressure pipes & fittings

- GB water supply pipes & fittings

- TIS water supply pipes & fittings

- DIN pipes & fittings for drainage

- DIN fittings for drainage with expanding

- ASTM D2665 fittings for drainage

- GB pipes & fittings for drainage

- GB insulating electrical pipes & fittings

- ASTM SCH40 water supply pipes & fittings

- GB fittings for drainage with gasket

- PE copolymer push-fittings series

- Brass compression fittings

- Copper plug-in quick connect fittings

- Brass/SS/Steel push-fittings series

- Irrigation sprinkler & accessories

- Garden hoses and eater hose barrow

- Galvanized Iron Fittings

- Metal hose and pipe clamp

- PP Plug-In Quick Connect Fittings

- SS/DI/CI/DCI/Steel valves

- SS201/SS304/SS316 Pipe Fittings

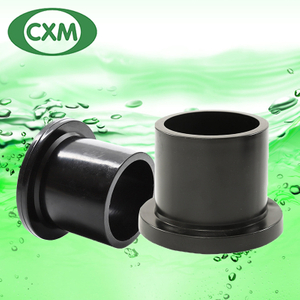

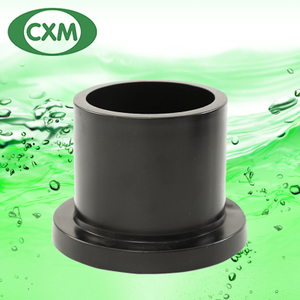

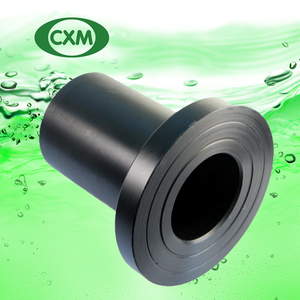

HDPE stub end with back ring

Pressure: SDR11,SDR13.6,SDR17

Process: butt fusion injection

Color: black, blue

Working medium: water,oil,gas

Working temperature: -40℃~40℃

Working life: more than 50 years

Size: dn20~dn1600

Means of transport: air or ocean

Trade term: FOB, CNF

Payment term: L/C, T/T

Production capacity: 100000pcs/month

Packing: export standard cartons

Delivery time: within 45 days

MOQ: 10pcs per size

Port of loading: Ningbo or Shanghai

Export area: all over the world

| Availability: | |

|---|---|

| Quantity: | |

-

CXM or OEM or withough brand

HDPE Butt Fusion Injection Stub End with Back Ring

***Advantages and welding of PE pipe fittings:

PE pipe fittings is light, which is more common for partial application pe80 pe100 grade level and two standards , including :

PE80 density of about 0.94 g / cm 3, PE100 density of about 0.96 g / cm 3 ;

Easy thermoplastic - easy to process ( such as injection molding, extrusion molding

Remanufacturing easy recycling

Good resistance to radiation and chemical stability

Good resistance to cold , the temperature can be -40 ℃ to

Excellent electrical insulation properties , is not affected by electrolytic corrosion

Malleable - extended break PE80> 700% PE100> 600%

Anti- erosion resistance - 8 times better than steel

Approximately half of the low thermal conductivity of glass

Smooth surface , unlike the role of metal pipes rust easily with oxygen crusts

pe pipe connection into fused pipe connections and fittings connected to melt , the more ordinary side, the other , as well as socket connections, this method is applied to a small size.

1 , fused connection : Follow these steps: First check , and then is cut pipe , pipe fittings joints clean , scrape the oxide layer , connecting the two parts of the tube and pipe fittings , calibration welder , welding parameter adjustment in accordance with the welding voltage, welding Dimensions , electricity, welding, and then finally cooled.

2, the hot melt connection : the inner surface of the pipe surface and the pipe is inserted while the welding is non-rotating die head is heated for a few seconds , then quickly removed and welding device , the heat pipe has a fast vertical insertion tube , packing, cooling to .

3 , socket connections, relatively simple, not elaborate here .

***Specifications:

| Size (mm) | Size(mm) | Size(mm) | Size(mm) | Size(mm) |

| dn20 | dn25 | dn32 | dn40 | dn50 |

| dn63 | dn75 | dn90 | dn110 | dn125 |

| dn140 | dn160 | dn180 | dn200 | dn225 |

| dn250 | dn280 | dn315 | dn355 | dn400 |

| dn450 | dn500 | dn560 | dn630 | dn710 |

| dn800 | dn900 | dn1000 | dn1200 | dn1400 |

| dn1600 |

HDPE Butt Fusion Injection Stub End with Back Ring

***Advantages and welding of PE pipe fittings:

PE pipe fittings is light, which is more common for partial application pe80 pe100 grade level and two standards , including :

PE80 density of about 0.94 g / cm 3, PE100 density of about 0.96 g / cm 3 ;

Easy thermoplastic - easy to process ( such as injection molding, extrusion molding

Remanufacturing easy recycling

Good resistance to radiation and chemical stability

Good resistance to cold , the temperature can be -40 ℃ to

Excellent electrical insulation properties , is not affected by electrolytic corrosion

Malleable - extended break PE80> 700% PE100> 600%

Anti- erosion resistance - 8 times better than steel

Approximately half of the low thermal conductivity of glass

Smooth surface , unlike the role of metal pipes rust easily with oxygen crusts

pe pipe connection into fused pipe connections and fittings connected to melt , the more ordinary side, the other , as well as socket connections, this method is applied to a small size.

1 , fused connection : Follow these steps: First check , and then is cut pipe , pipe fittings joints clean , scrape the oxide layer , connecting the two parts of the tube and pipe fittings , calibration welder , welding parameter adjustment in accordance with the welding voltage, welding Dimensions , electricity, welding, and then finally cooled.

2, the hot melt connection : the inner surface of the pipe surface and the pipe is inserted while the welding is non-rotating die head is heated for a few seconds , then quickly removed and welding device , the heat pipe has a fast vertical insertion tube , packing, cooling to .

3 , socket connections, relatively simple, not elaborate here .

***Specifications:

| Size (mm) | Size(mm) | Size(mm) | Size(mm) | Size(mm) |

| dn20 | dn25 | dn32 | dn40 | dn50 |

| dn63 | dn75 | dn90 | dn110 | dn125 |

| dn140 | dn160 | dn180 | dn200 | dn225 |

| dn250 | dn280 | dn315 | dn355 | dn400 |

| dn450 | dn500 | dn560 | dn630 | dn710 |

| dn800 | dn900 | dn1000 | dn1200 | dn1400 |

| dn1600 |