Product Category

- Hdpe Pipes & fittings

- PPR pipes & fittings

- Plastic butt welding machine

- PP compression fittings

- Pipe cutters

- Pressure testing pump

- PP thread fittings

- CPVC pressure pipes & fittings

- CPVC & PVC-U valves & faucets

- PUV-U pipes & fittings

- NBR 5648 water supply fittings

- ASTM SCH40 insulating electrical pipes & fittings

- ASTM SCH80 water supply pipes & fittings

- BS thread pipes & fittings

- GB PN16 pressure pipes & fittings

- GB water supply pipes & fittings

- TIS water supply pipes & fittings

- DIN pipes & fittings for drainage

- DIN fittings for drainage with expanding

- ASTM D2665 fittings for drainage

- GB pipes & fittings for drainage

- GB insulating electrical pipes & fittings

- ASTM SCH40 water supply pipes & fittings

- GB fittings for drainage with gasket

- PE copolymer push-fittings series

- Brass compression fittings

- Copper plug-in quick connect fittings

- Brass/SS/Steel push-fittings series

- Irrigation sprinkler & accessories

- Garden hoses and eater hose barrow

- Galvanized Iron Fittings

- Metal hose and pipe clamp

- PP Plug-In Quick Connect Fittings

- SS/DI/CI/DCI/Steel valves

- SS201/SS304/SS316 Pipe Fittings

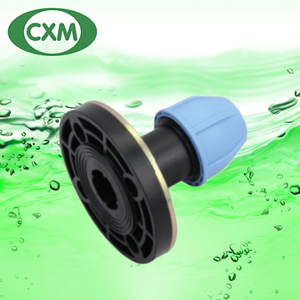

PP male threaded tee PP1012

Working pressure: PN16

Size: 16mm to 110mm

Color: Blue, Black, Sky Blue

MOQ: 10 cartons per size

Prices: FOB, CNF, EX-WORK

Payment terms: L/C, TT

Export to all over the world

Process: Injection

Thread: Male BSP

Suitable for irrigation and garden

| Availability: | |

|---|---|

| Quantity: | |

-

PP1012

-

CXM

PP male threaded tee

1.FIELDS OF APPLICATION

PP compression fittings and clamp saddles are designed specifically for cinnecting polyethylene pipes with an outside diameter of 16-110mm (135mm for clamp saddles). They are fully compatible with all PELD,PEHD,PE40,PE80 and PE100 pipes complying with EN12201,ISO4427,ISO14236,ISO13460,DIN8074. They are normally used to convey drinking water and fluids at pressure up to 16 bar for generic applications.The quality of the material used makes these fittings resistant to etching by numerous chemical substances and to UV-rays. The PP universal fitting can b e used to connect systems using PE metric piping with existing pipes made of any material,with external diameters of 15-34mm.

2.STANDARDS

1).Fittings and saddles

Complying with UNI 9561,UNI 9562,Din 8076-3,ISO 14236,ISO 13460

2).Threads

Complying with ISO7/1,DIN 2999,BS 21

3).Flanges

Complying with UNI 2278,DIN 8063

3.OPERATING TEMPERATURES

PP Fittings and clamp saddles are not suitable for use with hot water for the limits dictated by the use of polyethylene pipes.

Maximum operating temperatures refer to the use of polyethylene pipes; it is therfore necessary to refer to the regulations applicable in the country of use. The fittings and clamp saddles can with stand temperatures below 0ºC. The table below shows the maximum operating pressure during continuous operation (PFA) with changes in temperature if the liquid converyed is water,in compliance with EN 805,EN 12201 and ISO 13761. For values falling within the set range,alinear interpolation can be obtained.

| Operating T (ºC) | ≤20ºC | 25ºC | 30ºC | 35ºC | 40ºC | 45ºC |

| PFA (bar) | 16 | 14.9 | 13.9 | 12.8 | 11.8 | 10.8 |

| PFA (bar) | 10 | 9.3 | 8.7 | 8 | 7.4 | 6.7 |

4.SPECIFICATIONS:

| D(mm) | F(BSP) | PCS/CTN | MOQ(CTNS) | MOQ(PCS) |

| 20 | G 1/2"M | 120 | 10 | 1200 |

| 20 | G 3/4"M | 120 | 10 | 1200 |

| 25 | G 1/2"M | 80 | 10 | 800 |

| 25 | G 3/4"M | 80 | 10 | 800 |

| 25 | G 1"M | 80 | 10 | 800 |

| 32 | G 1"M | 48 | 10 | 480 |

| 40 | G 1-1/4"M | 32 | 10 | 320 |

| 50 | G 1-1/2"M | 30 | 10 | 300 |

| 63 | G 2"M | 12 | 10 | 120 |

| 75 | G 2-1/2"M | 6 | 10 | 60 |

| 90 | G 3"M | 6 | 10 | 60 |

| 110 | G 4"M | 4 | 10 | 40 |

PP male threaded tee

1.FIELDS OF APPLICATION

PP compression fittings and clamp saddles are designed specifically for cinnecting polyethylene pipes with an outside diameter of 16-110mm (135mm for clamp saddles). They are fully compatible with all PELD,PEHD,PE40,PE80 and PE100 pipes complying with EN12201,ISO4427,ISO14236,ISO13460,DIN8074. They are normally used to convey drinking water and fluids at pressure up to 16 bar for generic applications.The quality of the material used makes these fittings resistant to etching by numerous chemical substances and to UV-rays. The PP universal fitting can b e used to connect systems using PE metric piping with existing pipes made of any material,with external diameters of 15-34mm.

2.STANDARDS

1).Fittings and saddles

Complying with UNI 9561,UNI 9562,Din 8076-3,ISO 14236,ISO 13460

2).Threads

Complying with ISO7/1,DIN 2999,BS 21

3).Flanges

Complying with UNI 2278,DIN 8063

3.OPERATING TEMPERATURES

PP Fittings and clamp saddles are not suitable for use with hot water for the limits dictated by the use of polyethylene pipes.

Maximum operating temperatures refer to the use of polyethylene pipes; it is therfore necessary to refer to the regulations applicable in the country of use. The fittings and clamp saddles can with stand temperatures below 0ºC. The table below shows the maximum operating pressure during continuous operation (PFA) with changes in temperature if the liquid converyed is water,in compliance with EN 805,EN 12201 and ISO 13761. For values falling within the set range,alinear interpolation can be obtained.

| Operating T (ºC) | ≤20ºC | 25ºC | 30ºC | 35ºC | 40ºC | 45ºC |

| PFA (bar) | 16 | 14.9 | 13.9 | 12.8 | 11.8 | 10.8 |

| PFA (bar) | 10 | 9.3 | 8.7 | 8 | 7.4 | 6.7 |

4.SPECIFICATIONS:

| D(mm) | F(BSP) | PCS/CTN | MOQ(CTNS) | MOQ(PCS) |

| 20 | G 1/2"M | 120 | 10 | 1200 |

| 20 | G 3/4"M | 120 | 10 | 1200 |

| 25 | G 1/2"M | 80 | 10 | 800 |

| 25 | G 3/4"M | 80 | 10 | 800 |

| 25 | G 1"M | 80 | 10 | 800 |

| 32 | G 1"M | 48 | 10 | 480 |

| 40 | G 1-1/4"M | 32 | 10 | 320 |

| 50 | G 1-1/2"M | 30 | 10 | 300 |

| 63 | G 2"M | 12 | 10 | 120 |

| 75 | G 2-1/2"M | 6 | 10 | 60 |

| 90 | G 3"M | 6 | 10 | 60 |

| 110 | G 4"M | 4 | 10 | 40 |