Product Category

- Hdpe Pipes & fittings

- PPR pipes & fittings

- Plastic butt welding machine

- PP compression fittings

- Pipe cutters

- Pressure testing pump

- PP thread fittings

- CPVC pressure pipes & fittings

- CPVC & PVC-U valves & faucets

- PUV-U pipes & fittings

- NBR 5648 water supply fittings

- ASTM SCH40 insulating electrical pipes & fittings

- ASTM SCH80 water supply pipes & fittings

- BS thread pipes & fittings

- GB PN16 pressure pipes & fittings

- GB water supply pipes & fittings

- TIS water supply pipes & fittings

- DIN pipes & fittings for drainage

- DIN fittings for drainage with expanding

- ASTM D2665 fittings for drainage

- GB pipes & fittings for drainage

- GB insulating electrical pipes & fittings

- ASTM SCH40 water supply pipes & fittings

- GB fittings for drainage with gasket

- PE copolymer push-fittings series

- Brass compression fittings

- Copper plug-in quick connect fittings

- Brass/SS/Steel push-fittings series

- Irrigation sprinkler & accessories

- Garden hoses and eater hose barrow

- Galvanized Iron Fittings

- Metal hose and pipe clamp

- PP Plug-In Quick Connect Fittings

- SS/DI/CI/DCI/Steel valves

- SS201/SS304/SS316 Pipe Fittings

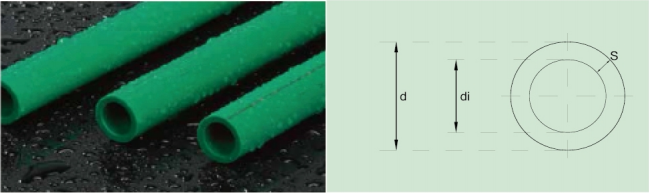

PPR pipes for cold and hot water XM1001

Material: 100% new materials PP-R

Brand Name: CXM

Specification: DN20 ~ DN160

Length: As customers' request

Thickness: International standard

Standard: DIN8077/8078,GB/T18742

Working Medium: Cold and Hot Water

Working Pressure: PN10/PN12.5/PN16/PN20/PN25

Working Temperature: -40℃~95℃

Connector: Welding

Color: Green, Grey, White,Blue

MOQ: 3000Meters

Export Area: All over the world

Trade Term: FOB,CFR

Payment Term: L/C,T/T

Means of transport: Land,Ocean,Air

Delivery Time: Within 30 Days

| Availability: | |

|---|---|

| Quantity: | |

-

XM1001

-

CXM or OEM or without brand

PP-R pipes for cold and hot water SDR11/SDR9/SDR7.4/SDR6

***Application Scope

▇ Residential cold and hot water piping;

▇ Piping for purified water or drinking water;

▇ Production and conveyance system for beverage and liquid medicament;

▇ Piping used for compressed air;

▇ Piping used for other industries and agriculture.

***Overview

PP-R pipe,also called random copolymerized polypropylene (type II) pipe, is a new generation of environment-friendly construction material developed in the 1990s. Besides plastic pipes' merits such as lightness,corrosion resistance,anti-deposition and long service life, PP-R pipe also enjoy some other advantages,like hygienicness,heatresistance and longer service life. Meanwhile, its coefficient of heat conductivity is quite low and it is good at hear preservation and energy conservation. Because of the technique of the thermosol binding, it is convenient to be installed and reliable in joints. Also, the material can be recycled. Therefore, it is worthy of the name environment-friendly construction material.

Compated with aluminum multiunit pipe,PP-R pipe can be made into tubular products with larger calibers, with the largest reaching more than 160mms in caliber. CXM brand PP-R pipes and fittings are widely used in such areas as delivery of drinking water, production agriculture, planting in gardens, parks and ranches, etc.

***Color: green, white,bray,blue,yellow

***Length: 4meters straight length or according to customers' requirement.

***Technology Data:

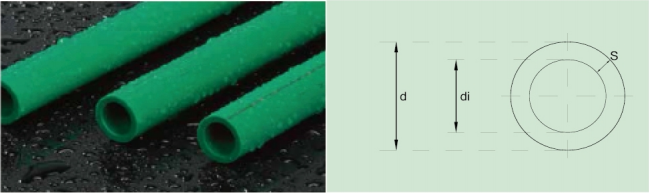

| ||||

| Pipe Series: PP-R PIPE SDR11/S5/PN10/PN12.5/1.0MPa/1.25MPa/10Bars/12.5Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.0mm | 100m | 20mm | 2.0mm | 16.0mm |

| 25x2.3mm | 60m | 25mm | 2.3mm | 20.4mm |

| 32x3.0mm | 40m | 32mm | 3.0mm | 26.0mm |

| 40x3.7mm | 28m | 40mm | 3.7mm | 32.6mm |

| 50x4.6mm | 16m | 50mm | 4.6mm | 40.8mm |

| 63x5.8mm | 12m | 63mm | 5.8mm | 51.40mm |

| 75x6.9mm | 8m | 75mm | 6.9mm | 61.20mm |

| 90x8.2mm | 4m | 90mm | 8.2mm | 73.6mm |

| 110x10.3mm | 4m | 110mm | 10.3mm | 89.4mm |

| 160x14.6mm | 4m | 160mm | 14.6mm | 130.8mm |

| Pipes Series: PP-R PIPE SDR9/S4/PN16/1.6MPa/16Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.3mm | 100m | 20mm | 2.3mm | 15.4mm |

| 25x2.8mm | 60m | 25mm | 2.8mm | 19.4mm |

| 32x3.6mm | 40m | 32mm | 3.6mm | 24.8mm |

| 40x4.5mm | 28m | 40mm | 4.5mm | 31.0mm |

| 50x5.6mm | 16m | 50mm | 5.6mm | 38.8mm |

| 63x7.1mm | 12m | 63mm | 7.1mm | 48.8mm |

| 75x8.4mm | 8m | 75mm | 8.4mm | 58.2mm |

| 90x10.1mm | 4m | 90mm | 10.1mm | 69.8mm |

| 110x12.2mm | 4m | 110mm | 12.2mm | 85.6mm |

| 160x17.8mm | 4m | 160mm | 17.8mm | 124.4mm |

| Pipes Series: PP-R PIPE SDR7.4/S3.2/PN20/2.0MPa/20bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.8mm | 100m | 20mm | 2.8mm | 14.4mm |

| 25x3.5mm | 60m | 25mm | 3.5mm | 18.0mm |

| 32x4.4mm | 40m | 32mm | 4.4mm | 23.2mm |

| 40x5.5mm | 28m | 40mm | 5.5mm | 29.0mm |

| 50x6.9mm | 16m | 50mm | 6.9mm | 36.2mm |

| 63x8.7mm | 12m | 63mm | 8.7mm | 45.6mm |

| 75x10.1mm | 8m | 75mm | 10.1mm | 54.8mm |

| 90x12.3mm | 4m | 90mm | 12.3mm | 65.4mm |

| 110x15.1mm | 4m | 110mm | 15.1mm | 79.8mm |

| 160x21.8mm | 4m | 160mm | 21.8mm | 116.4mm |

| Pipe Series: PP-R PIPE SDR6.0/S2.5/PN25/2.5MPa/25Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x3.4mm | 100m | 20mm | 3.4mm | 13.2mm |

| 25x4.2mm | 60m | 25mm | 4.2mm | 16.6mm |

| 32x5.4mm | 40m | 32mm | 5.4mm | 21.2mm |

| 40x6.7mm | 28m | 40mm | 6.7mm | 26.6mm |

| 50x8.3mm | 16m | 50mm | 8.3mm | 33.4mm |

| 63x10.5mm | 12m | 63mm | 10.5mm | 42.0mm |

| 75x12.3mm | 8m | 75mm | 12.3mm | 50.4mm |

| 90x15.0mm | 4m | 90mm | 15.0mm | 60.0mm |

| 110x18.3mm | 4m | 110mm | 18.3mm | 73.4mm |

Installation Instructions:

PP-R pipes and fittings should be connected through thermal melting or electric meltling, relevant set of welding machine or tool is supplied by us. Pipe installation and operation must comply with relevant technology regulation and usage requirement for welding machine tool.

CXM brand PP-R pipe can not directly be connected to sanitary ware, metal pipe and fittings,valves,relevant accessories, but via PP-R metal threaded fittings or flange.

Welding Key Point:

Cut the part of pipe at right angle to pipe axis with pipe cutter, take care that pipe axis is free from burrs or cutting chips and remove if necessary.

Do not start operation until green ligh is on.

Welding parts of pipes and fittings must be kept dry, cleanness, no oil.

Marking welding depth at end of pipe and fittings with proper pen and measure in accordance with following table.

After stipulates the heating time, quickly remove pipe and fittings from welding die, jointing them immediately with average and without truning until the marked depth is bead of PP-R from the fitting.

Joint element have to be fixed during the specified assembly time. use time to correct the connection. The connection is only restricted to the aligrement of pipe and fittings. Never turn the elements or align the connection after the processing time.

| Dimension (mm) | Welding Depth (mm) | Heating Time (s) | Welding Time (s) | Cooling Time (min) |

| 16 | 13.0 | 5 | 4 | 2 |

| 20 | 14.0 | 5 | 4 | 2 |

| 25 | 15.0 | 7 | 4 | 2 |

| 32 | 16.5 | 8 | 6 | 4 |

| 40 | 18.0 | 12 | 6 | 4 |

| 50 | 20.0 | 18 | 6 | 4 |

| 63 | 24.0 | 24 | 8 | 6 |

| 75 | 26.0 | 30 | 8 | 8 |

| 90 | 29.0 | 40 | 8 | 8 |

| 110 | 32.5 | 50 | 10 | 8 |

| 160 | 55.0 | 60 | 15 | 10 |

PP-R pipes for cold and hot water SDR11/SDR9/SDR7.4/SDR6

***Application Scope

▇ Residential cold and hot water piping;

▇ Piping for purified water or drinking water;

▇ Production and conveyance system for beverage and liquid medicament;

▇ Piping used for compressed air;

▇ Piping used for other industries and agriculture.

***Overview

PP-R pipe,also called random copolymerized polypropylene (type II) pipe, is a new generation of environment-friendly construction material developed in the 1990s. Besides plastic pipes' merits such as lightness,corrosion resistance,anti-deposition and long service life, PP-R pipe also enjoy some other advantages,like hygienicness,heatresistance and longer service life. Meanwhile, its coefficient of heat conductivity is quite low and it is good at hear preservation and energy conservation. Because of the technique of the thermosol binding, it is convenient to be installed and reliable in joints. Also, the material can be recycled. Therefore, it is worthy of the name environment-friendly construction material.

Compated with aluminum multiunit pipe,PP-R pipe can be made into tubular products with larger calibers, with the largest reaching more than 160mms in caliber. CXM brand PP-R pipes and fittings are widely used in such areas as delivery of drinking water, production agriculture, planting in gardens, parks and ranches, etc.

***Color: green, white,bray,blue,yellow

***Length: 4meters straight length or according to customers' requirement.

***Technology Data:

| ||||

| Pipe Series: PP-R PIPE SDR11/S5/PN10/PN12.5/1.0MPa/1.25MPa/10Bars/12.5Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.0mm | 100m | 20mm | 2.0mm | 16.0mm |

| 25x2.3mm | 60m | 25mm | 2.3mm | 20.4mm |

| 32x3.0mm | 40m | 32mm | 3.0mm | 26.0mm |

| 40x3.7mm | 28m | 40mm | 3.7mm | 32.6mm |

| 50x4.6mm | 16m | 50mm | 4.6mm | 40.8mm |

| 63x5.8mm | 12m | 63mm | 5.8mm | 51.40mm |

| 75x6.9mm | 8m | 75mm | 6.9mm | 61.20mm |

| 90x8.2mm | 4m | 90mm | 8.2mm | 73.6mm |

| 110x10.3mm | 4m | 110mm | 10.3mm | 89.4mm |

| 160x14.6mm | 4m | 160mm | 14.6mm | 130.8mm |

| Pipes Series: PP-R PIPE SDR9/S4/PN16/1.6MPa/16Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.3mm | 100m | 20mm | 2.3mm | 15.4mm |

| 25x2.8mm | 60m | 25mm | 2.8mm | 19.4mm |

| 32x3.6mm | 40m | 32mm | 3.6mm | 24.8mm |

| 40x4.5mm | 28m | 40mm | 4.5mm | 31.0mm |

| 50x5.6mm | 16m | 50mm | 5.6mm | 38.8mm |

| 63x7.1mm | 12m | 63mm | 7.1mm | 48.8mm |

| 75x8.4mm | 8m | 75mm | 8.4mm | 58.2mm |

| 90x10.1mm | 4m | 90mm | 10.1mm | 69.8mm |

| 110x12.2mm | 4m | 110mm | 12.2mm | 85.6mm |

| 160x17.8mm | 4m | 160mm | 17.8mm | 124.4mm |

| Pipes Series: PP-R PIPE SDR7.4/S3.2/PN20/2.0MPa/20bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x2.8mm | 100m | 20mm | 2.8mm | 14.4mm |

| 25x3.5mm | 60m | 25mm | 3.5mm | 18.0mm |

| 32x4.4mm | 40m | 32mm | 4.4mm | 23.2mm |

| 40x5.5mm | 28m | 40mm | 5.5mm | 29.0mm |

| 50x6.9mm | 16m | 50mm | 6.9mm | 36.2mm |

| 63x8.7mm | 12m | 63mm | 8.7mm | 45.6mm |

| 75x10.1mm | 8m | 75mm | 10.1mm | 54.8mm |

| 90x12.3mm | 4m | 90mm | 12.3mm | 65.4mm |

| 110x15.1mm | 4m | 110mm | 15.1mm | 79.8mm |

| 160x21.8mm | 4m | 160mm | 21.8mm | 116.4mm |

| Pipe Series: PP-R PIPE SDR6.0/S2.5/PN25/2.5MPa/25Bars | ||||

| Size | Packing Quantity | Diameter | Thicknesss | Internal Diameter |

| mm | meters/bag | d (mm) | s (mm) | di (mm) |

| 20x3.4mm | 100m | 20mm | 3.4mm | 13.2mm |

| 25x4.2mm | 60m | 25mm | 4.2mm | 16.6mm |

| 32x5.4mm | 40m | 32mm | 5.4mm | 21.2mm |

| 40x6.7mm | 28m | 40mm | 6.7mm | 26.6mm |

| 50x8.3mm | 16m | 50mm | 8.3mm | 33.4mm |

| 63x10.5mm | 12m | 63mm | 10.5mm | 42.0mm |

| 75x12.3mm | 8m | 75mm | 12.3mm | 50.4mm |

| 90x15.0mm | 4m | 90mm | 15.0mm | 60.0mm |

| 110x18.3mm | 4m | 110mm | 18.3mm | 73.4mm |

Installation Instructions:

PP-R pipes and fittings should be connected through thermal melting or electric meltling, relevant set of welding machine or tool is supplied by us. Pipe installation and operation must comply with relevant technology regulation and usage requirement for welding machine tool.

CXM brand PP-R pipe can not directly be connected to sanitary ware, metal pipe and fittings,valves,relevant accessories, but via PP-R metal threaded fittings or flange.

Welding Key Point:

Cut the part of pipe at right angle to pipe axis with pipe cutter, take care that pipe axis is free from burrs or cutting chips and remove if necessary.

Do not start operation until green ligh is on.

Welding parts of pipes and fittings must be kept dry, cleanness, no oil.

Marking welding depth at end of pipe and fittings with proper pen and measure in accordance with following table.

After stipulates the heating time, quickly remove pipe and fittings from welding die, jointing them immediately with average and without truning until the marked depth is bead of PP-R from the fitting.

Joint element have to be fixed during the specified assembly time. use time to correct the connection. The connection is only restricted to the aligrement of pipe and fittings. Never turn the elements or align the connection after the processing time.

| Dimension (mm) | Welding Depth (mm) | Heating Time (s) | Welding Time (s) | Cooling Time (min) |

| 16 | 13.0 | 5 | 4 | 2 |

| 20 | 14.0 | 5 | 4 | 2 |

| 25 | 15.0 | 7 | 4 | 2 |

| 32 | 16.5 | 8 | 6 | 4 |

| 40 | 18.0 | 12 | 6 | 4 |

| 50 | 20.0 | 18 | 6 | 4 |

| 63 | 24.0 | 24 | 8 | 6 |

| 75 | 26.0 | 30 | 8 | 8 |

| 90 | 29.0 | 40 | 8 | 8 |

| 110 | 32.5 | 50 | 10 | 8 |

| 160 | 55.0 | 60 | 15 | 10 |